Powered by AM 2.0

Revolutionary advancements in Additive Manufacturing (AM) have made the mass fabrication of custom-fit products a reality. The inconsistency of stone age modeling is over, ushering in an era of high-precision standardized custom-fit.

Finally, the future fits.

What Makes Us Different?

At TruFIT Customs our mission is to bring the advantages of 3D technology to your doorstep.

Over the past decade, 3D print and scan technology has evolved to allow the mass fabrication of high-precision custom-fit products.

Each stage of our manufacturing process is optimized to ensure the highest accuracy so that you can experience your true fit.

Say goodbye to the expensive and time-consuming stone age and welcome to the future of custom-fit.

“Our equipment is optimized for the highest level of accuracy at every step.”

WorkFlow

Custom-Fit Measured in Micrometers

STEP 1

Scan

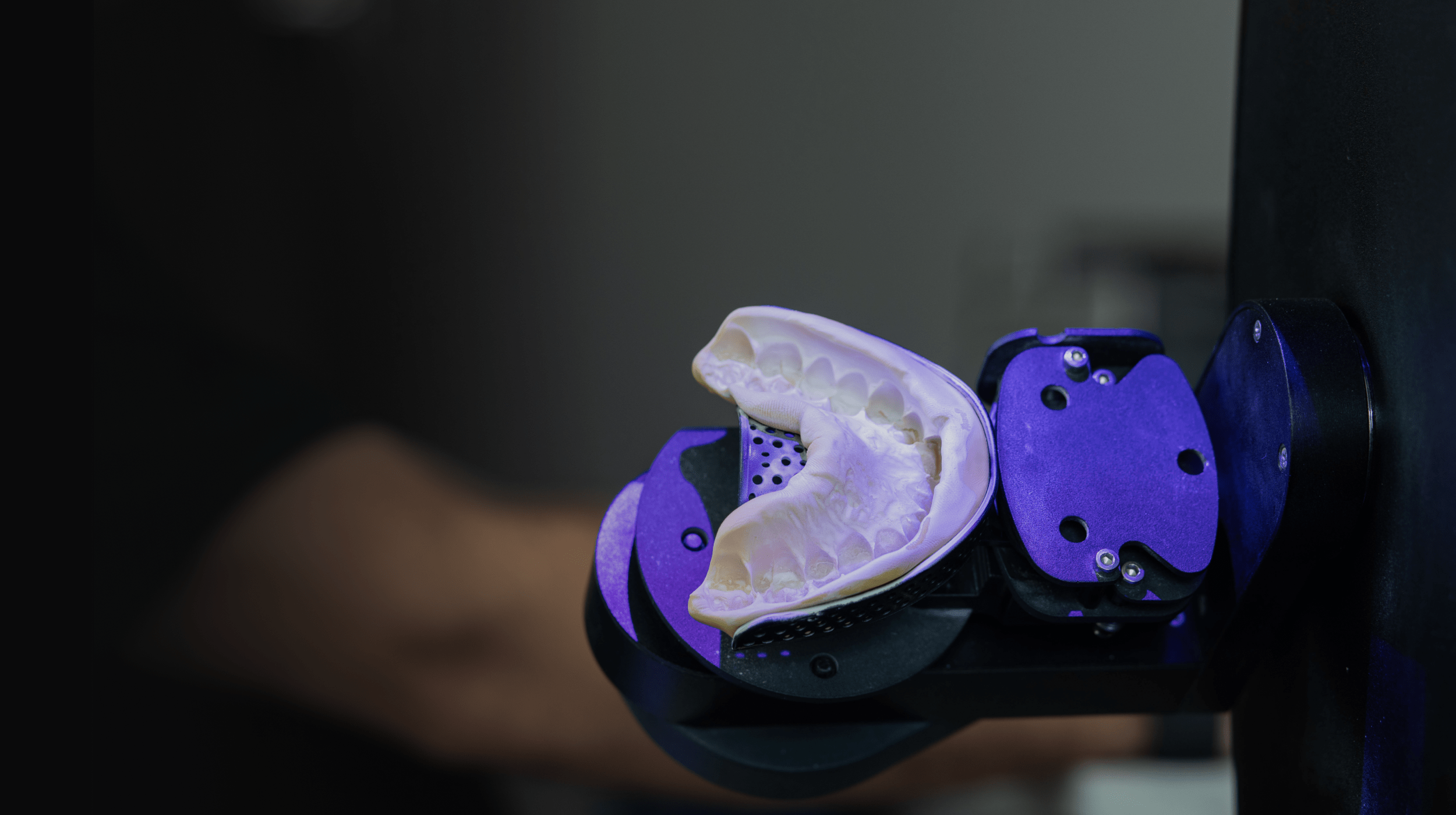

When your impression is received at our lab, it is digitized using a 405-nanometer light-based scanner to capture all intricacies to produce the most accurate results possible. Guaranteed.

STEP 2

Design

Our team of highly skilled CAD professionals designs and optimizes your digital model to ensure a precise fit that maximizes comfort before sending it to print.

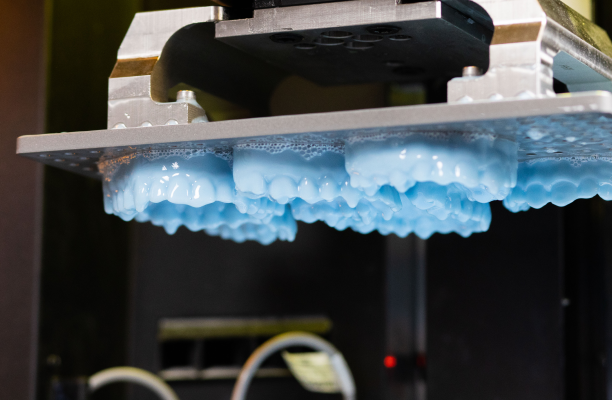

STEP 3

Your optimized digital file is brought to life by photopolymerizing each layer using the latest high-precision digital light projection (DLP) 3D print technology.

Light-Based Scanner

Each impression is uniquely scanned to capture every detail and contour.

Laser 3D Printing

Automated layer-based 3D printing system brings your impression to life.

Professional CAD Design

With over 20+ years of dental CAD experience, our design team can optimize and/or repair your impression to ensure the best fit.

Comfort Measured in Nanometers

Say goodbye to painful stock-fit products. The future of custom-fit has finally arrived!